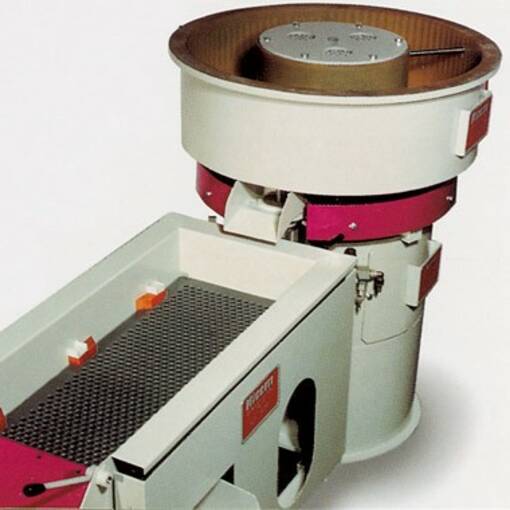

Industrial washing and degreasing machine with a rotating basket, suitable for workshops, production lines, and maintenance operations. Constructed from stainless steel and designed to operate in a closed circuit, the unit employs a nozzle system that recirculates water and detergent to achieve uniform and efficient cleaning of parts placed in the rotating basket.

Main Features:

- Stainless steel construction for corrosion resistance and ease of cleaning.

- Closed-loop washing system with water and detergent recirculation, optimizing consumption and solution recovery.

- Rotating basket that ensures uniform cleaning of metal or plastic parts.

- Nozzle bank and recirculation pump for removal of oils and greases from machining or stamping operations.

- Compatibility with biodegradable detergents, reducing environmental impact.

- Applicable for both maintenance and implementation in production cells and industrial processes (machining, stamping, tool cleaning, etc.).

X81 range models (examples available):

- L55: basket diameter 600 mm; tank capacity 80 L; basket load capacity: 100 (depending on configuration).

- L90: basket diameter 780 mm; tank capacity 85 L; basket load capacity: 150 (depending on configuration).

Options and customization:

- Possibility to manufacture machines with modifications in height and weight.

- Option to add additional elements (accessories and specific adaptations according to industrial application).

Benefits for your company:

- Reduction in cleaning times and reproducible result standards.

- Lower detergent and water consumption thanks to the recirculation system.

- Versatility to clean a wide variety of parts in industrial environments.

Available for configuration and sizing according to the needs of each industrial process.