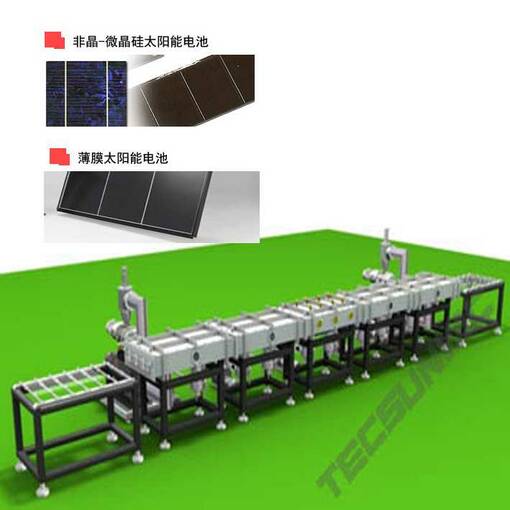

Physical Vapor Deposition (PVD) metallization machine designed to apply metallic and functional coatings on substrates such as plastics, glass, films, optical components, and decorative pieces. These systems operate in a vacuum chamber and allow the production of thin, uniform, and adherent layers for decorative, reflective, barrier, and functional applications in industrial sectors.

Key Features

- Technology: Physical Vapor Deposition (PVD) in a vacuum chamber; typical configurations include evaporation and/or sputtering (magnetron) depending on the application.

- Typical Components: Vacuum chamber, deposition sources, pumping and vacuum system, rotary manipulator/support for substrates, electronic control for process parameters (temperature, pressure, power).

- Flexibility: Suitable for processing rolls (), flat pieces, or batches of parts according to the machine design.

- Advantages: High uniformity and adhesion coatings, nanoscale thickness control, lower contamination, and good aesthetic finish.

Recommended Applications

- Packaging industry and metallized films

- Optical components and reflective mirrors

- Decorative parts and accessories for automotive and household appliances

- Electronics and sensors requiring conductive or reflective layers

- Barrier and functional coatings for technical parts

Options and Customization

- Process configurations (thermal evaporation, e-beam, sputtering) according to material and deposition requirements

- Vacuum chamber size and capacity designed to measure for continuous production or batch processing

- Integration of control and monitoring systems for process traceability

Depositable Materials (Examples)

- Metals: Aluminum, copper, chromium, gold, silver (depending on process and compatibility)

- Composites and conductive/transparent oxides via advanced PVD techniques

Additional Information

- Demo videos of the equipment in operation are available on the product sheet.

- To select a model, production capacity, and budget, it is recommended to specify the type of substrate, format (roll or parts), required performance, and desired coating type.

Product Details

Country of origin:

China

Industrial sector: