Heavy-duty fluoroplastic centrifugal transfer pump engineered for safe, continuous handling of highly corrosive liquids and solvents. Designed for chemical process, petrochemical and industrial service, the pump’s wetted parts and casing are molded from fluoroplastic alloys (F46 / PVDF / FEP) to provide long-term resistance to acids, alkalis, salts, strong oxidizers and other aggressive media.

Key features

- Corrosion-resistant fluoroplastic construction (F46 / PVDF / FEP) for wetted components and pump casing

- Continuous-duty centrifugal design with compact, serviceable construction

- Flow range: 3 to 200 m3/h; head range: 10 to 80 m

- Operating temperature range: 20°C to 100°C

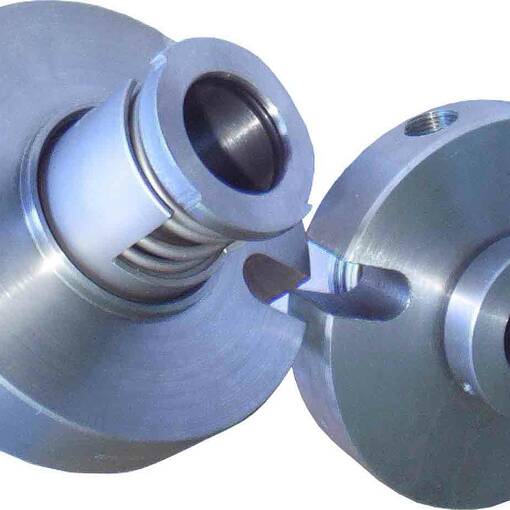

- Two drive configurations: FSB-L (shaft coupling) and FSB-D (close-coupled)

- Seal options: advanced external PTFE bellows mechanical seal with multi-layer protection; for liquids containing solids a single-end hard-face (silicon carbide vs silicon carbide) mechanical seal is available

- Motor options: standard or explosion-proof (Ex), 3‑phase 50 Hz (380–415 V) or 3‑phase 60 Hz (440–460 V)

Typical applications

Suitable for transfer of corrosive liquids in industries such as petrochemical, chemical manufacturing, pharmaceuticals, pesticides, pickling, dyes and pigments, coatings, metallurgy, pulp & paper, electroplating and food processing (where compatible). Commonly used for acid, alkali and solvent transfer, recirculation and dosing tasks where chemical resistance and seal reliability are critical.

Model notation and selection guidance

- Example: FSB50-30D / FSB50-30L

- FSB = fluoroplastic chemical pump

- 50 = inlet diameter in mm

- 30 = nominal delivery head in meters

- D = close-coupled (no shaft coupling)

- L = shaft-coupled (with coupling)

Selection notes

- Choose FSB-L for installations requiring a separate coupling and easier in-line maintenance; choose FSB-D for compact, direct-driven layouts.

- Specify the mechanical seal type based on solid content of the fluid: use the hard-face silicon carbide-to-silicon carbide seal for abrasive or particulate-laden fluids.

- Confirm motor specification (standard vs Ex-proof, voltage/frequency) for site electrical compatibility.

Documents and customization

Technical drawings, hydraulic curves and material certificates are typically provided on request to support system integration and piping design. Custom material or seal combinations and explosion-proof motor options are available for specific service conditions.