High-strength ASTM A516 pressure-vessel steel plates (Grade 70) designed for welded fabrication where good notch toughness is required. A516 Grade 70 is a carbon (non‑stainless) steel plate commonly specified for boilers, pressure vessels and other high‑pressure equipment used in intermediate and low temperature service.

Key features

- Conforms to the ASTM A516/A516M Grade 70 specification for pressure‑vessel plate (Grade 60 also commonly available).

- Engineered for welded construction: reactors, heat exchangers, separators, spherical tanks, liquefied gas cylinders, boiler steam drums, nuclear reactor pressure vessel shells, hydropower components and similar high‑pressure equipment.

- Delivered with mill inspection documentation and original inspection reports; third‑party inspection (for example SGS or other independent certifiers) can be arranged prior to shipment.

- Suppliers can provide documented approvals from recognized classification and certification bodies (TÜV, Lloyd’s Register) where required by project specs.

Quality & testing

- Material supplied as carbon/alloy pressure vessel plate with mechanical properties and impact toughness appropriate for Grade 70 service per ASTM A516.

- Acceptance of third‑party inspection and testing (SGS and similar) is supported; standard delivery paperwork includes mill test certificates (MTCs) and inspection reports.

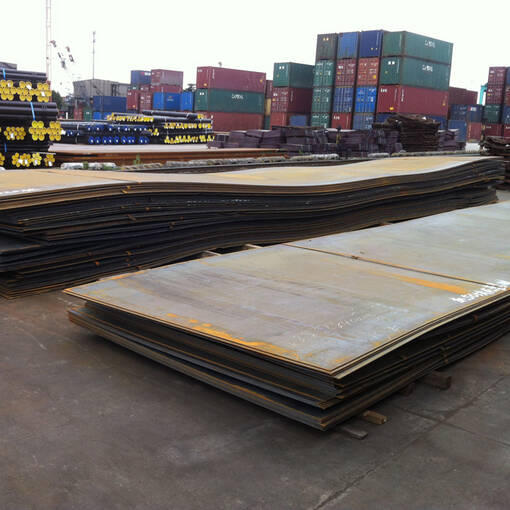

Packaging & logistics

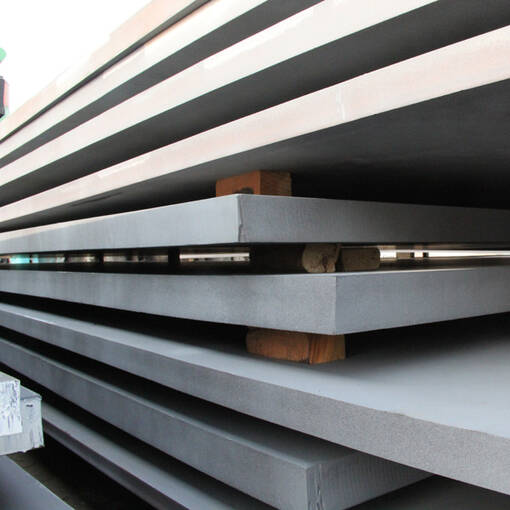

- Export packing: strapped and secured on flat pallets/wooden supports, suitable for container shipment.

- Typical container loading capacity (approximate, depends on plate sizes and stacking):

- 20ft GP: ~24–26 m3, up to ~23 metric tonnes per container

- 40ft GP: ~54 m3, up to ~27 metric tonnes per container

- 40ft HQ: ~68 m3, up to ~27 metric tonnes per container

- International shipping arranged via established carriers; insurance and freight options can be coordinated to meet buyer requirements.

After-sales & service

- Pre-shipment inspection coordination, shipment tracking and delivery updates provided.

- Post‑delivery technical support available for installation/fabrication queries and to resolve quality issues in accordance with agreed warranty/contract terms.

Typical buyers

- Pressure vessel and boiler fabricators, EPC contractors, petrochemical plants, power stations, cryogenic and LNG equipment manufacturers, and industrial OEMs requiring certified plate for welded high‑pressure applications.