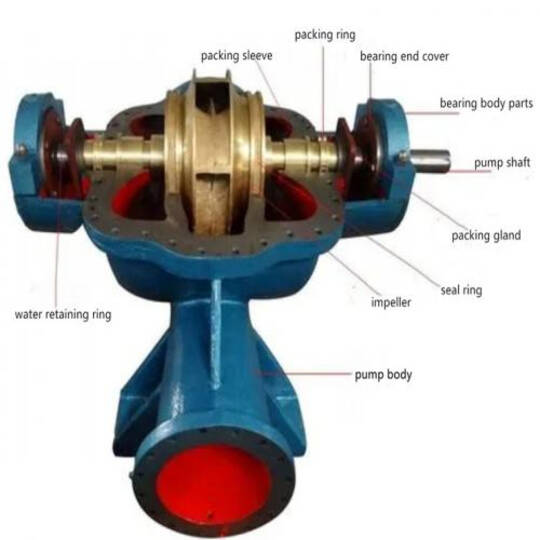

Horizontal split-case double-suction centrifugal pump designed for high-flow liquid transfer in industrial and municipal applications. The S/SH pump uses a back-to-back (double) impeller arrangement that draws liquid into the impeller from both sides, doubling flow capacity for a given impeller diameter while substantially reducing axial thrust. Its horizontally split casing permits rapid on-site inspection and maintenance without disturbing the pump alignment or piping.

Key features

- Double-suction, back-to-back impellers for high flow and improved hydraulic balance

- Horizontally split volute casing for easy inspection, servicing and rotor access

- Inlet and outlet arranged in the same direction and perpendicular to the shaft to simplify piping layout and installation

- Reduced axial thrust compared with single-suction designs, improving bearing life and reliability

- Suitable for continuous duty and large-capacity pumping systems

Typical applications

- Water supply and distribution

- HVAC and chilled water systems

- Cooling water circulation for industrial processes and power plants

- Irrigation and large-scale agricultural pumping

- Municipal and utility waterworks

Operational advantages

- Higher flow capacity per impeller diameter than single-suction pumps

- Easier maintenance and lower downtime thanks to split-case construction

- Stable operation with lower vibration and improved mechanical balance

Notes for specification and selection

- Confirm required flow, head, suction conditions (NPSH), and operating liquid to select the correct size and materials

- Review coupling, driver (motor), and baseplate requirements to ensure alignment and vibration control

- Specify sealing arrangement (mechanical seal or packing) and bearing lubrication method according to service conditions

If you need detailed hydraulic curves, material options, dimensional drawings, or performance tables for model 150S-100, request those specifications to match the pump to your system requirements.