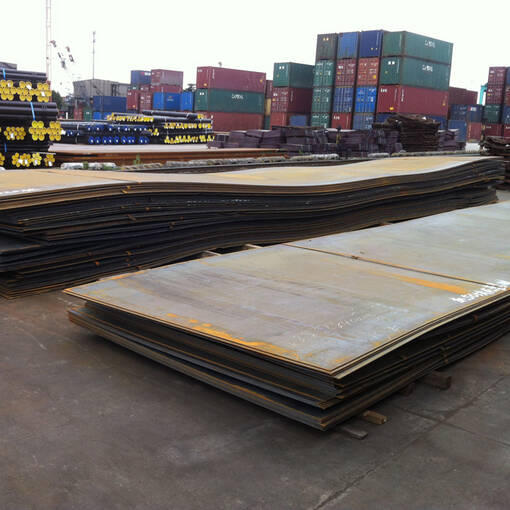

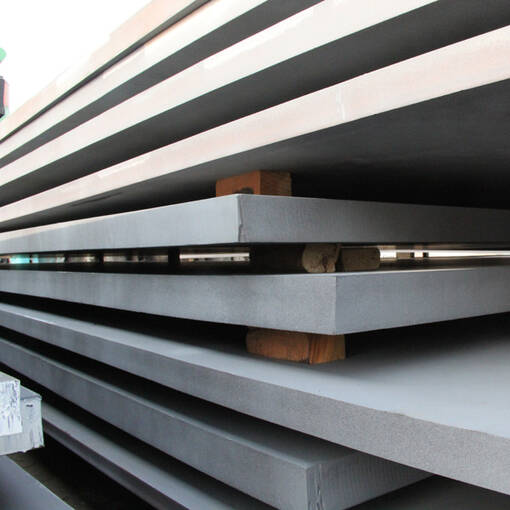

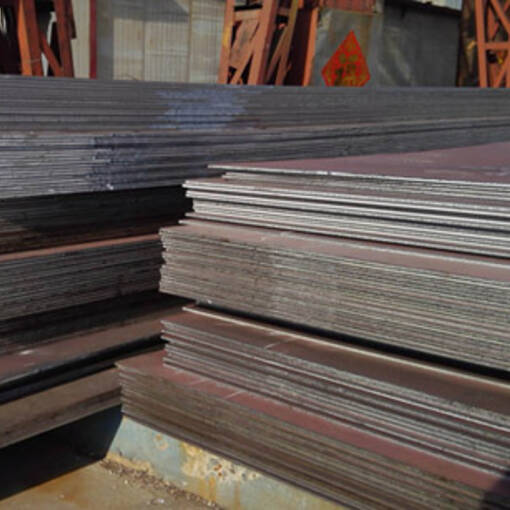

ASME A/SA 302 Grade B alloy steel plates engineered for welded boilers, pressure vessels and heavy fabrication where high strength and good weldability are required. These plates are a manganese–molybdenum alloy steel grade supplied to meet pressure-retaining applications and are offered with factory test documentation and optional post-processing services for turnkey supply.

Key mechanical characteristics

- Minimum yield strength: 345 MPa

- Tensile strength range: 550–690 MPa

Standards, testing and quality documentation

- Supplied to ASME A/SA 302 Grade B specification

- Mill test certificate issued in EN 10204 format (original)

- High-tensile testing and low-temperature impact testing available

- Normalizing heat treatment for plate thicknesses over 40 mm

- Simulated post-weld heat treatment (PWHT) on request

- Rolling and acceptance available to NACE MR0175 requirements (HIC & SSCC) where required

Available fabrication and finishing services

- Cutting, bevelling and bespoke processing to customer drawings

- Shot blasting and painting / protective coating

- Welding to buyer specification and supply of welded test reports

Typical applications

- Industrial and utility boilers

- Pressure vessels and storage tanks

- Heat exchangers and piping components

- Heavy fabrication for rail, pipework and structural applications

Supply options and ordering

Plates can be supplied with specified mechanical test reports and non-destructive or destructive test records as required by project specifications. Contact your supplier with required plate dimensions, thickness, certifications and any post-processing or testing requirements to obtain lead times and quotes.