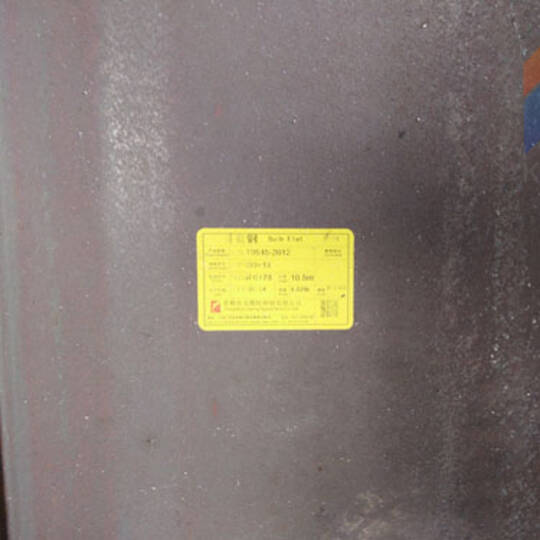

Manganese‑molybdenum alloy steel plate engineered for welded boilers and pressure-vessel fabrication. Conforming to ASME SA302 Grade A (A302 A), the plate is supplied as a fully killed steel with enhanced mechanical strength and toughness for high‑temperature, high‑pressure service.

Key mechanical properties

- Minimum yield strength: 310 MPa

- Tensile strength: 515–655 MPa

Standards & compliance

- ASME SA302 Grade A (A302 A)

- Original mill test certificate issued under EN 10204

Quality control & available tests/services

- High-tension (tensile) testing

- Low-temperature impact testing

- Normalizing for plates thicker than 40 mm

- Simulated post-weld heat treatment (PWHT)

- Rolling to NACE MR0175 requirements where required (HIC + SSCC)

- Cutting, shot blasting, painting and welding to end-user specifications

Typical applications

- Industrial and utility boilers

- Pressure vessels and heat-exchangers

- Heavy fabrications where high strength and post-weld performance are required

- Marine and shipbuilding structural components, where alloy performance is needed

Supply options

Plates can be supplied with full traceability documentation (mill test certificate) and processed (cut-to-size, surface preparation, painting or welding) per purchaser requirements. Contact your supplier to confirm available thicknesses, plate sizes and lead times.

Product Details

Harmonized commodity

Country of origin:

China

Industrial sector: