Formulated rubber mixture for vulcanization processes, manufactured from virgin rubber and devulcanized rubber in elastomers. It is designed to be processed in industrial operations of calendering, extrusion, and molding, offering an adaptable base for obtaining vulcanized parts with adjustable mechanical and resistance properties according to the application.

Key Features:

- Custom formulations: possibility to adjust the composition to achieve different hardness, elasticity, and wear resistance.

- Compatibility with industrial processes: suitable for heat vulcanization and transformation through calendering, extrusion, and compression or injection molding.

- Mixed base of elastomers: combines virgin rubber and devulcanized rubber to optimize cost and performance according to technical specifications.

- Optional additives and reinforcements: fillers (carbon black or others), plasticizing oils, curatives, and functional additives can be incorporated as required.

- Quality control: available with batch tests and controls (Mooney viscosity, consistency, moisture/impurities content) under agreed specifications.

Typical Applications:

- Tires and retreading

- Industrial and hydraulic hoses

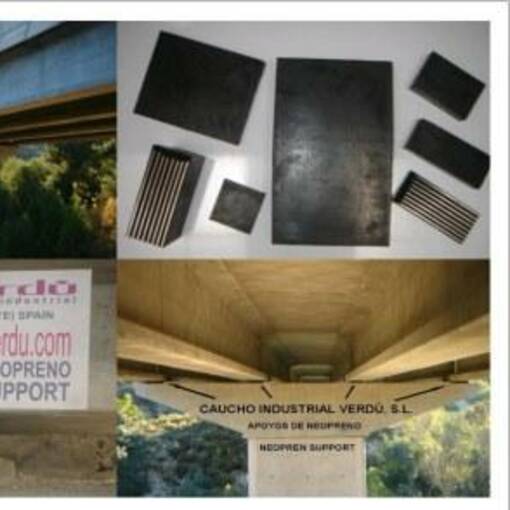

- Profiles and sealing gaskets

- Molded parts and components (O-rings, gaskets, covers)

- Extruded articles and belts

Presentation and logistics:

- Delivery in pressed bales, bags, or granulated formats according to processing needs.

- Packaging and labeling adaptable to logistic requirements and B2B traceability.

- Storage recommendations: keep in dry, cool, and protected from direct light to maintain properties before processing.

Customization and technical support:

We offer formulation development according to performance requirements (hardness, elongation, thermal and chemical resistance) and process specifications. Batches can be accompanied by quality certificates and technical data sheets upon request.

Product Details

Country of origin:

Colombia

Industrial sector: