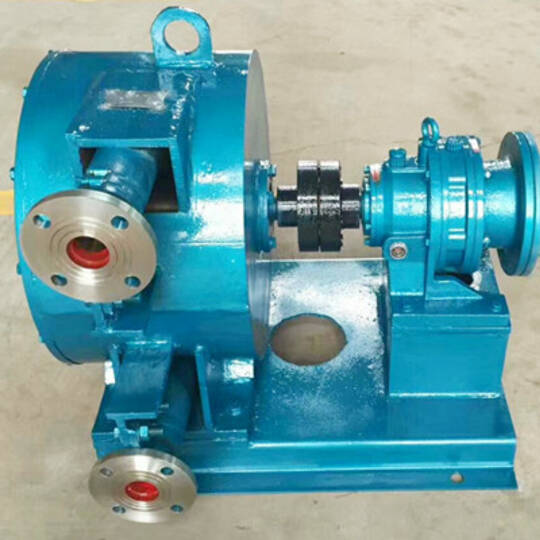

Robust, seal-less peristaltic (hose) pump engineered for industrial transfer, dosing and metering of abrasive, viscous or solids-bearing fluids. The pump’s fluid path is limited to the replaceable hose, eliminating mechanical seals and the risk of leakage or cross-contamination while simplifying maintenance.

Key features

- Seal-less design: only the hose contacts the pumped medium, minimizing leakage and contamination risk.

- Reversible operation for flexible process control and flushing.

- Strong self-priming capability (maximum suction height: 8 m).

- Handles high-viscosity, high-density fluids and fluids with suspended solids (impurity/fiber diameter must be less than 1/4 of the pump tube inner diameter).

- Simple construction and maintenance: quick hose replacement, no gland packing or mechanical seals to service.

- Accurate metering potential and low pulsation compared with some positive-displacement options; suitable as a metering pump in many uses.

How it works

A set of compression rollers travels along a flexible hose, pinching and releasing the tube to create local vacuum and pressure zones. Fluid is drawn into the hose as it returns to its round shape and is then displaced forward by the moving compression zone.

Typical applications

- Chemical processing: acids, alkalis, inorganic slurries and corrosive fluids where hose material compatibility is selected.

- Pharmaceuticals: transfer of drug liquids where contamination control is critical.

- Food & beverage: pumping oils, syrups and other non-solvent food liquids (select food-grade hoses as required).

- Mining, metallurgy and pulp industries: ore slurries, paper pulp and other abrasive slurries.

- Water and wastewater treatment: lime slurry, silt and sludge handling.

- Construction materials: cement mortar, ceramic glazes, concrete additives.

- Oil & gas and drilling operations: drilling mud and similar fluids.

- Industrial waste and specialty fluids: electrolytic waste, paints, adhesives, latexes and other high-viscosity or particle-laden media.

Benefits for B2B buyers

- Lower downtime and maintenance cost due to simple hose replacement and absence of mechanical seals.

- Reduced environmental and workplace risk from leak-free operation.

- Flexible integration into dosing and transfer systems; can replace reciprocating, diaphragm or screw pumps in many rubber-resistant applications.

Notes

- Select hose material and pump tube diameter to match chemical compatibility, temperature, abrasion and allowed particle size limits (impurity diameter < 1/4 of tube ID).

- Specify the model and hose material required for your application when requesting a quote or technical datasheet. Model example: 80RGB-13-6.

Product Details

Harmonized commodity

Brand:

kenshine-pump

Country of origin:

China

Industrial sector:

SKU:

SET

GTIN/EAN:

841360

MPN:

RGB

Model:

80RGB-13-6

Unit type:

Set

Minimum order (MOQ):

1