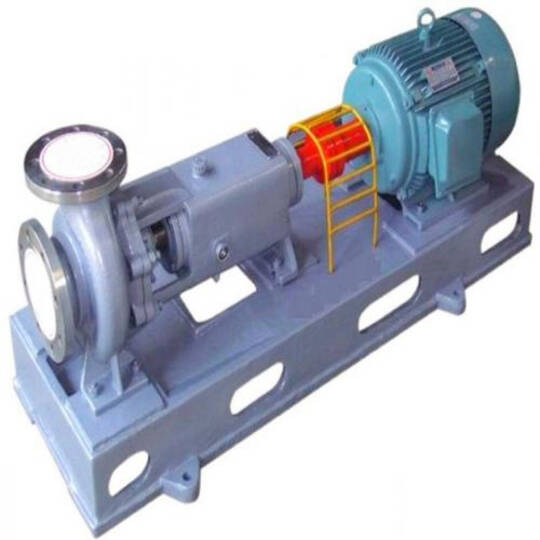

Robust single-stage, single-suction cantilever centrifugal pump engineered for corrosive and alkali liquids in industrial processes. Designed as an evolution of the IH series and built to ISO2858 (performance and dimensions) and ISO5199 (manufacturing) standards, this pump handles liquids containing crystals or suspended solids (solid content up to ~50%) and viscous media common in chemical, alkali and process industries.

Key features

- Single-stage, single-suction cantilever centrifugal design for compact footprint and easy inline installation

- Shortened impeller cantilever and thicker shaft diameter to reduce rotor deflection and increase mechanical strength

- Asymmetric-volute casing without mouth rings to reduce hydraulic losses and shrink casing size

- Integrated impeller nut to improve inlet conditions and enhance anti-cavitation performance

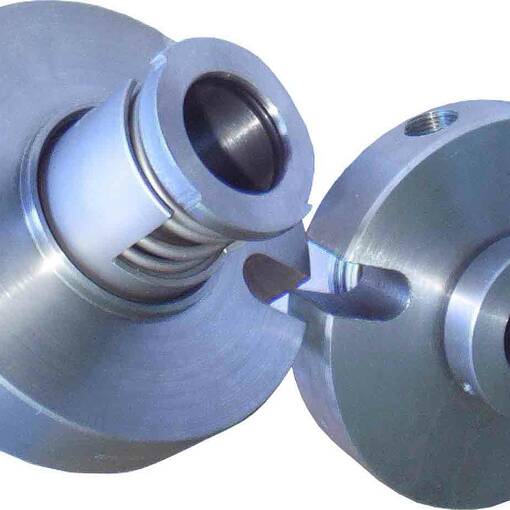

- New shaft sealing arrangements offered: advanced double-face mechanical seal style or packing-type seals for improved leakage control

- Triple-bearing support (three imported bearings) for improved rotor stability and extended seal and bearing life

- Clearance adjustable without disassembling pump casing or impeller, reducing downtime and maintenance labor

Performance and compliance

- Manufactured to ISO2858 (dimensions/performance) and ISO5199 (technical manufacturing conditions)

- Optimized hydraulic design for higher efficiency versus legacy IH-series pumps when handling viscous or solids-bearing fluids

Typical applications

- Alkali and caustic processing

- Salt and chemical production

- Petrochemical and refining operations

- Pulp and paper, pulp processing

- Power plants and coal chemical processes

- Pharmaceutical, sugar and steelmaking plants

- Water treatment and surface preparation processes (degreasing, phosphating, electrophoresis)

Operational benefits for buyers

- Better handling of viscous, solids-containing and corrosive liquids with improved efficiency

- Reduced leakage and longer seal life from advanced sealing options and improved shaft rigidity

- Lower maintenance time and cost due to clearance adjustment without full disassembly

- Compact casing and reduced hydraulic losses through asymmetric volute design

Selection notes (provide these to supplier)

When requesting quotations or sizing, include design flow (m3/h), total head (m), liquid temperature, viscosity, solids content and particle size, pH/corrosiveness, required materials of construction, and preferred seal type. This ensures correct material selection and seal arrangement for alkali or corrosive service.