Vertical inline centrifugal pump with a fluorine-plastic lining designed for reliable, long-term handling of highly corrosive liquids. The pump combines a cast iron or cast steel casing with a fluorine-plastic inner lining to deliver excellent chemical resistance while retaining the mechanical strength of metallic components.

Key features

- Corrosion-resistant fluorine-plastic lining — protects the wet parts from acids, alkalis, oxidants and other aggressive media across a wide concentration range.

- Vertical inline configuration — inlet and outlet share the same centerline and diameter for compact, space-saving installation; optional protective cover enables outdoor installation.

- Efficient hydraulic design — developed from proven domestic hydraulic profiles and IS centrifugal-pump performance parameters to provide high hydraulic efficiency and energy savings.

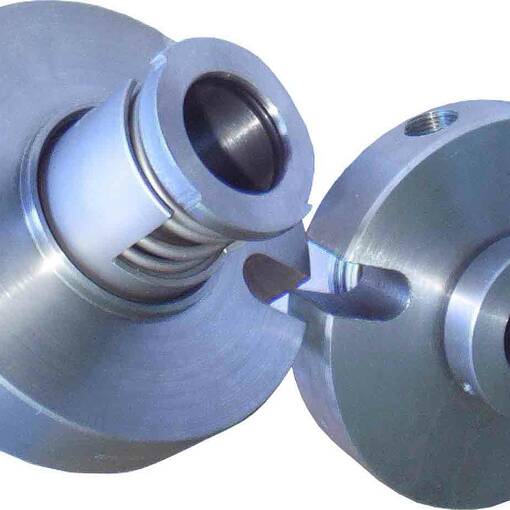

- Directly mounted impeller — impeller is installed directly on the motor bearing for a short axial length and compact structure; pump/motor bearing arrangement balances radial and axial loads to reduce vibration and noise.

- Robust shaft sealing options — standard seals, abrasion-resistant mechanical seals, or combined mechanical seal arrangements to extend seal life in abrasive or corrosive services.

- Flexible deployment — pumps may be operated in series or parallel to meet required flow and head conditions.

Performance and operating conditions

- Suitable for pumping acids, alkalis, oxidizing liquids and other corrosive fluids at arbitrary concentrations.

- Service temperature range: approximately -85 °C to 200 °C (confirm for your application and local regulations).

- Designed to provide low noise, stable operation and reliable performance; often specified as a cost-effective alternative to pumps fabricated from 316L stainless steel or titanium alloys.

Typical industries and applications

- Chemical processing, petrochemical and refining

- Metallurgy and power generation

- Flue gas desulfurization and dust-removal systems

- Pulp & paper, textile and synthetic-fiber production

- Food and pharmaceutical process lines (where compatible with regulatory requirements)

Notes for specification and selection

- Verify the exact fluorine-plastic type, lining thickness and motor/impeller materials for compatibility with your fluid, temperature and pressure conditions.

- Select appropriate mechanical seal type and materials when solids, abrasives or severe oxidants are present.

- For series/parallel operation, confirm hydraulic curves and motor ratings to ensure stable combined operation.

Contact your technical sales or engineering representative with pump model (e.g., GDF40-160), required flow/head, operating temperature and fluid composition to obtain detailed performance curves and material certifications.

Product Details

Harmonized commodity

Brand:

kenshine-pump

Country of origin:

China

Industrial sector:

SKU:

600SETS

GTIN/EAN:

841370

MPN:

GDF\/GBF

Model:

GDF40-160

Unit type:

Set

Minimum order (MOQ):

1