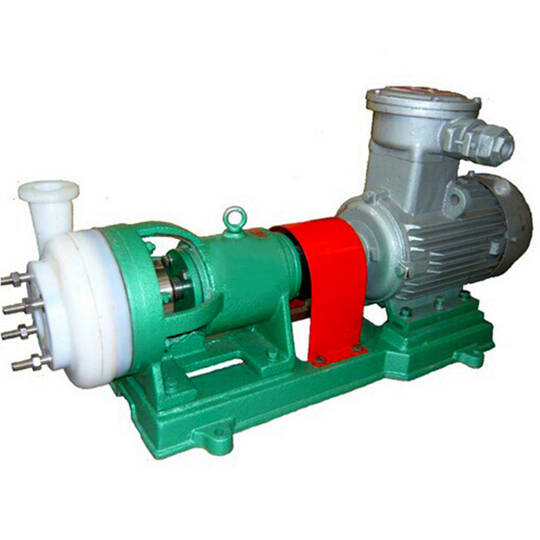

A horizontally mounted fluoroplastic centrifugal transfer pump engineered for safe, low-maintenance handling of highly corrosive liquids. All wetted flow parts are made from fluoroplastic alloy and the pump casing is constructed from F46 plastic, giving excellent resistance to strong acids, alkalis and oxidizing agents without aging or chemical decomposition.

Key features

- Fluoroplastic-wetted components (impeller, casing, liners) for maximum corrosion resistance

- Cantilever (overhung) shaft design — pump cannot support pipeline weight; mount piping independently

- Outside-mounted PTFE bellows mechanical seal with multi-level protection to extend seal life

- Option for a single-face hard mechanical seal (silicon carbide vs. silicon carbide) when handling liquids containing solids — select seal type based on suspended solid content

- Two package configurations:

- FSB-L: pump and motor connected via flexible shaft coupling (easier alignment and maintenance)

- FSB-D: close-coupled pump and motor (compact footprint)

- Major components (housing, impeller, seals) are interchangeable between FSB-L and FSB-D

- Lightweight construction for easier handling and reduced maintenance labor compared with lined metal pumps

Applications

Designed for demanding chemical-processing environments including petrochemical, chemical manufacturing, pharmaceuticals, pesticides, pickling and plating, dye, paint, smelting, pulp & paper, electroplating and food-processing industries where aggressive, corrosive or oxidizing liquids must be transferred safely.

Selection and operation notes

- Confirm suspended solid content before choosing a seal option (hard mechanical seal recommended for abrasive particles)

- Because the pump is a cantilever design, piping should be independently supported so the pump does not carry pipe weight

- Check compatibility of F46 and fluoroplastic alloys with the specific media and operating temperature in your process

Benefits

Corrosion-resistant wet-end materials, modular seal options, and interchangeable components deliver reduced downtime, longer service life in aggressive media, and lower maintenance costs in industrial chemical transfer applications.