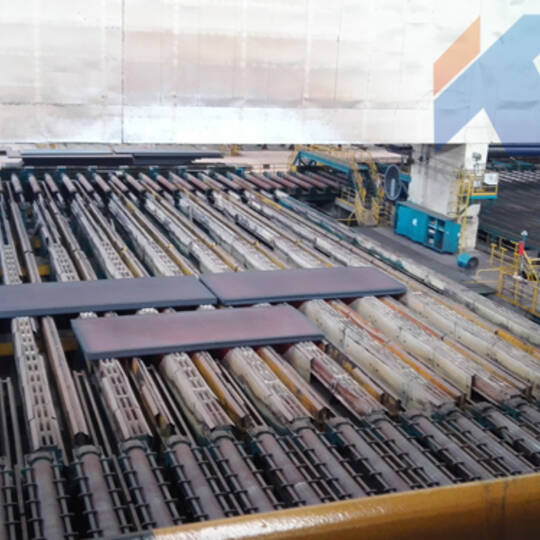

High-strength manganese–molybdenum alloy steel plates engineered for welded boilers, pressure vessels and heavy-duty structural applications. These ASME-grade plates are supplied to meet the mechanical and inspection requirements typical of SA A302 Grade D material and are suitable where high yield and good toughness are required.

Key mechanical properties

- Minimum yield strength: 345 MPa

- Tensile strength range: 550–690 MPa

- Fully killed steel with Mn–Mo alloying to improve strength and toughness

Quality, inspection and heat treatment options

- Mill test certificate issued to EN 10204 standard (original MTC available)

- High-tension (tensile) testing

- Low-temperature impact (Charpy) testing for toughness verification

- Normalizing for thicknesses over 40 mm

- Simulated post-weld heat treatment (PWHT) where required

- Manufacturing and rolling available to meet NACE MR0175 requirements (including HIC and SSCC controls) for sour-service suitability

Processing and finishing services (available on request)

- Shot blasting and primer/paint systems

- Cutting to size, beveling and edge preparation

- Welding to customer specifications

- Custom fabrication and further machining as required

Typical applications

- Industrial boilers and pressure vessels

- Petrochemical and power generation plants

- Offshore and marine structures where high toughness is required

- Heavy fabrication, structural and transportation components

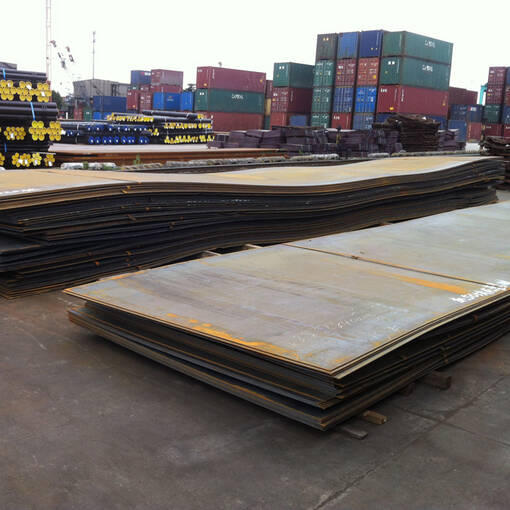

Ordering and supply

- Standard mill certificates and test reports provided with shipments

- For pricing, lead time and available plate sizes / thicknesses please submit an RFQ with required dimensions, quantity and any specified tests or certifications.

Product Details

Harmonized commodity

Brand:

Katalor

Country of origin:

China

Industrial sector: