A molybdenum-alloy pressure-vessel plate manufactured to ASTM A204 Grade B specification, engineered for welded boilers, pressure vessels and high-temperature service where increased strength and creep resistance are required. Plates are supplied as‑fabricated (no temper or additional heat treatment) and are produced to meet the chemical and mechanical test requirements called out in the ASTM A204 specification.

Key features

- Conforms to ASTM A204 Grade B specification for molybdenum alloy steel plates used in welded boilers and pressure vessels.

- Designed for welded fabrication and high-temperature service where alloying with molybdenum improves strength and performance.

- Supplied as‑fabricated (no tempering or post‑fabrication heat treatment) and subject to the tension and chemical composition tests required by the specification.

Mechanical properties (as specified)

- Tensile strength (Rm): approximately 620 MPa at 20 °C

- Yield strength (YS): approximately 275 MPa at 20 °C

Chemical considerations

- Alloying includes molybdenum; the specification controls carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulphur (S) and molybdenum (Mo) to achieve required mechanical properties and weldability. Actual composition values and mill test reports are supplied per order and inspection requirements.

Available grades and forms

- ASTM A204 is published with three grades (A, B, C). Grade B represents the mid‑range strength level between Grade A and Grade C.

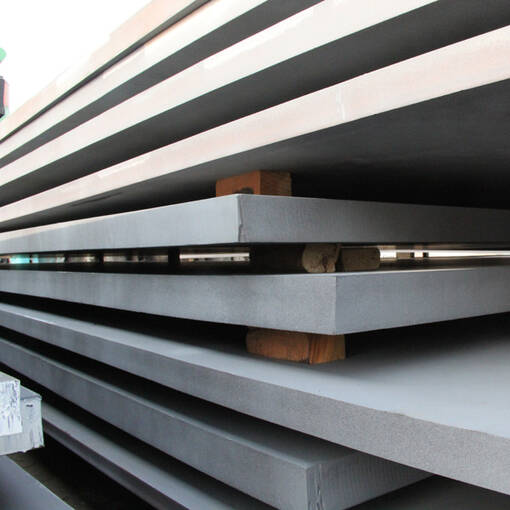

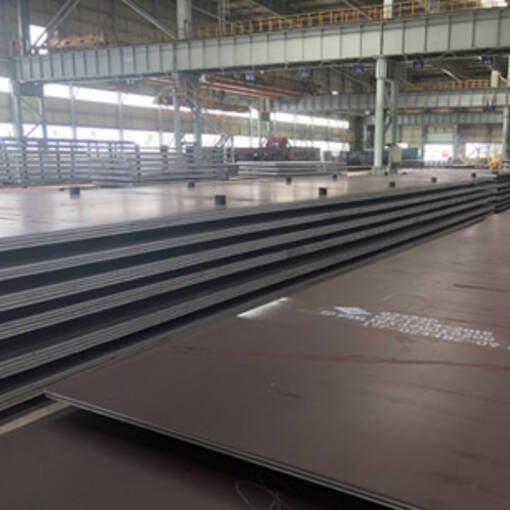

- Typical supply form: flat plates for fabrication into welded pressure-retaining components. Plates can be furnished with mill test certificates, material traceability and inspection documentation on request. Cut-to-size, surface finish and tolerance options are subject to supplier capability and order agreement.

Applications

- Boiler plate for high-pressure steam boilers

- Pressure vessel shells and heads

- Heat exchangers and high-temperature welded components

Ordering and quality

- Specify ASTM A204 Grade (A/B/C), plate dimensions, required testing/certificates (e.g., MTC / EN 10204), and any special surface or cutting requirements when requesting a quote. Tension test and chemical analysis are performed to validate conformity to the specification.