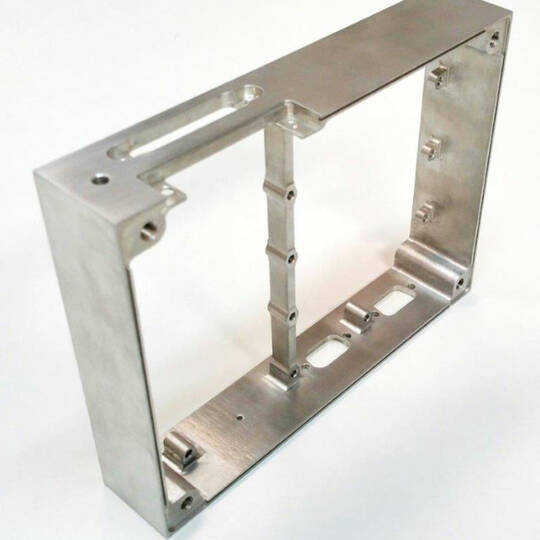

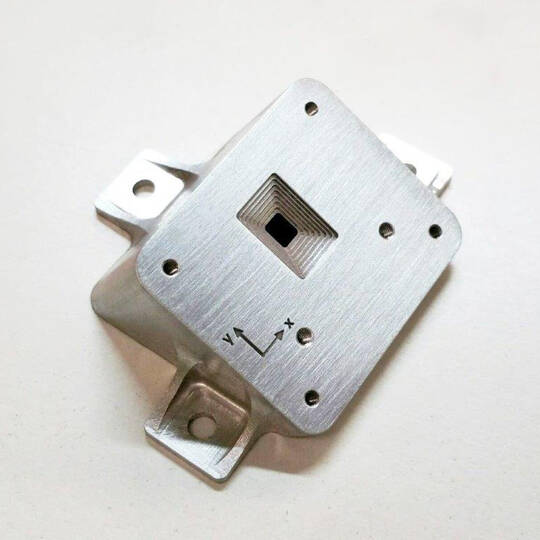

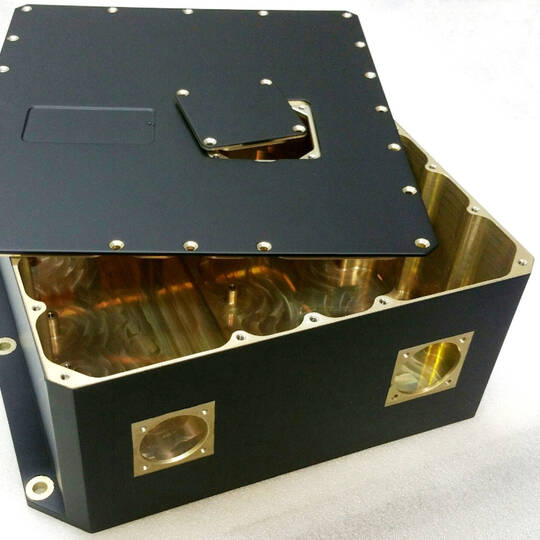

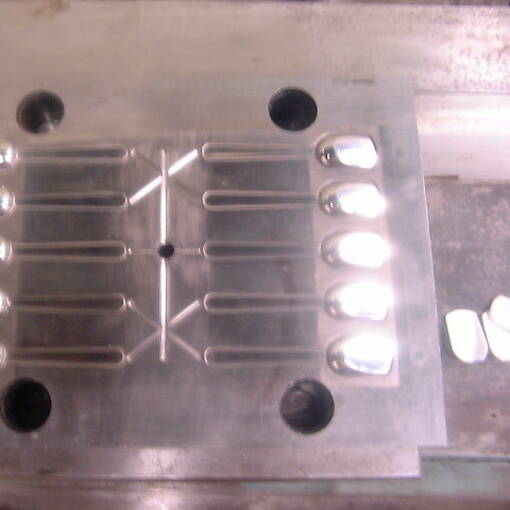

Precision CNC‑machined housings designed for appliances and electronics. Manufactured on 3‑ to 5‑axis CNC centres, these housings combine tight dimensional control with repeatable surface finish and detailing (milling, drilling, tapping, and engraving) to meet functional and aesthetic requirements for enclosures, instrument casings, mounting frames and similar components.

Key capabilities

- Processes: 3‑ and 5‑axis CNC milling, contouring, slotting and precision engraving.

- Materials: commonly produced in aluminium, stainless steel, brass and engineering plastics; custom materials accommodated on request.

- Secondary operations: threaded holes, reaming, countersinks, inserts and precision bore finishing. Post‑process finishing options include anodizing, plating, passivation, powder coating and custom painting (available per project).

- Tolerances & quality: manufactured to tight tolerances required by electronics and appliance applications; full per‑part inspection and documentation available on request (dimensional checks, visual inspection, first article reports).

- Production scale: from single prototypes and small runs to medium and high‑volume production batches with consistent repeatability.

Why choose these housings

- Designed for fit and function: support for common CAD formats (STEP, IGES, DWG) and collaboration on design‑for‑manufacture (DFM) to reduce cost and improve assembly.

- Traceable, packaged and ready for assembly: parts can be batch‑labelled, kitted and packed to customer specifications for immediate use in production lines.

- Flexible lead times: options for quick‑turn prototype machining or scheduled production runs depending on your supply needs.

What we need to get started

Please provide part drawings or 3D models (STEP, IGES, or native CAD), material specification, required surface finish, tolerances and target quantities. Quotes include machining strategy, lead time and any recommended secondary finishing to meet functional or regulatory needs.

Product Details

Harmonized commodity

Country of origin:

Spain

Industrial sector: