High-performance horizontal, single-stage, single-suction centrifugal pump engineered for chemical process applications. Built to DIN24256 / ISO2858 dimensional and performance standards, this CZ-series pump delivers wide operating coverage and improved efficiency and cavitation performance compared with earlier IH-series designs.

Key performance and operating limits

- Flow rate: 3.2 – 2,000 m3/h

- Head: 7 – 160 m

- Maximum working pressure: 2.5 MPa

- Operating temperature range: -80 °C to 300 °C

Design highlights

- Horizontal back-pull-out (back door) construction for fast maintenance: the pump casing and impeller can be removed without disconnecting the piping or motor.

- Single-stage, open impeller with shaft coupling to motor; installed on a common baseplate for rigid alignment and reduced shaft deflection under pipe loads.

- Three-bearing rotor support with oil-lubricated bearings and oil-level sight glass for condition monitoring.

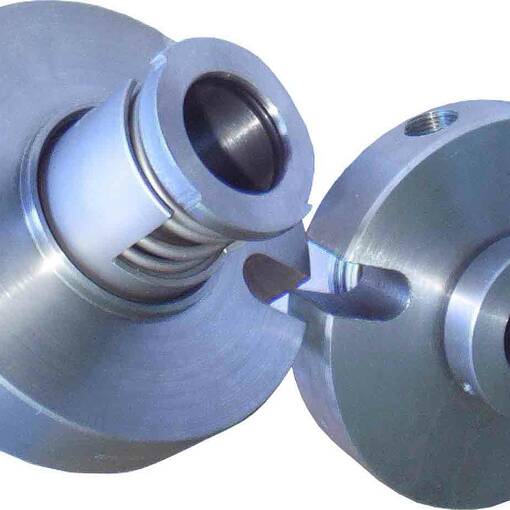

- Shaft sealing options: gland packing, single mechanical seal, or double mechanical seal (external seal piping and cooling provisions available).

- External mechanical seal cooling and bearing cooling provisions for high-temperature or demanding services.

- Cast pump body with integral feet to carry pipe loads directly to the foundation, protecting the rotor and mechanical seal for longer service life.

Materials and suitability

- Available materials: stainless steels (SS304, SS316, SS316L), duplex stainless steels (2205, 2507), titanium alloy, and other alloy options on request.

- Suitable for: low- to high-temperature liquids, neutral or corrosive media, and liquids containing suspended solids (depending on material and impeller selection).

- Typical industries: chemical and petrochemical plants, oil refineries, pulp and paper, and food processing.

Operational benefits for buyers

- Wide performance envelope covers many process duties, reducing SKUs and simplifying spare-parts inventories.

- Robust base-mounted design minimizes shaft deflection and extends seal and bearing life under heavy piping loads.

- Service-friendly construction reduces downtime: routine maintenance and seal replacement can be performed without disconnecting the pump from the line.

- Multiple seal and material options allow configuration for corrosive, abrasive or high-temperature process streams.

Typical scope of supply (configurable)

- Pump assembly (casing, impeller, shaft, bearings)

- Baseplate and coupling

- Selected seal type (packing / single / double mechanical seal)

- Cooling/seal support systems if required

- Material certification and dimensional drawing package on request

For specification, selection and spare-parts inquiries, provide required duty point (flow, head, temperature, pressure) and process fluid details so the pump can be configured to meet your application.

Product Details

Harmonized commodity

Brand:

kenshine-pump

Country of origin:

China

Industrial sector:

SKU:

SET

GTIN/EAN:

841370

MPN:

CZ/IH/ZA

Model:

CZ/IH/ZA

Unit type:

Set

Minimum order (MOQ):

1